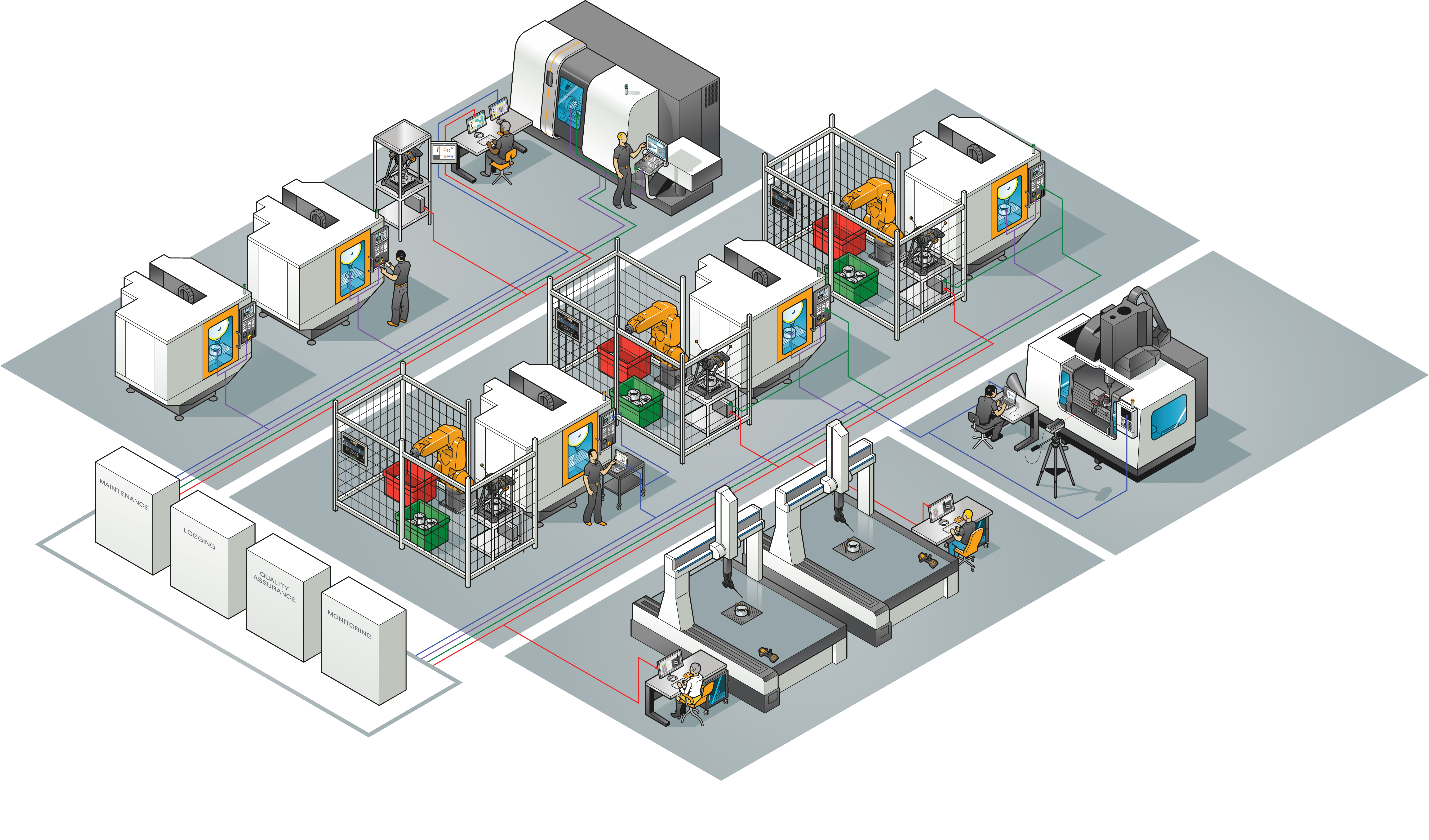

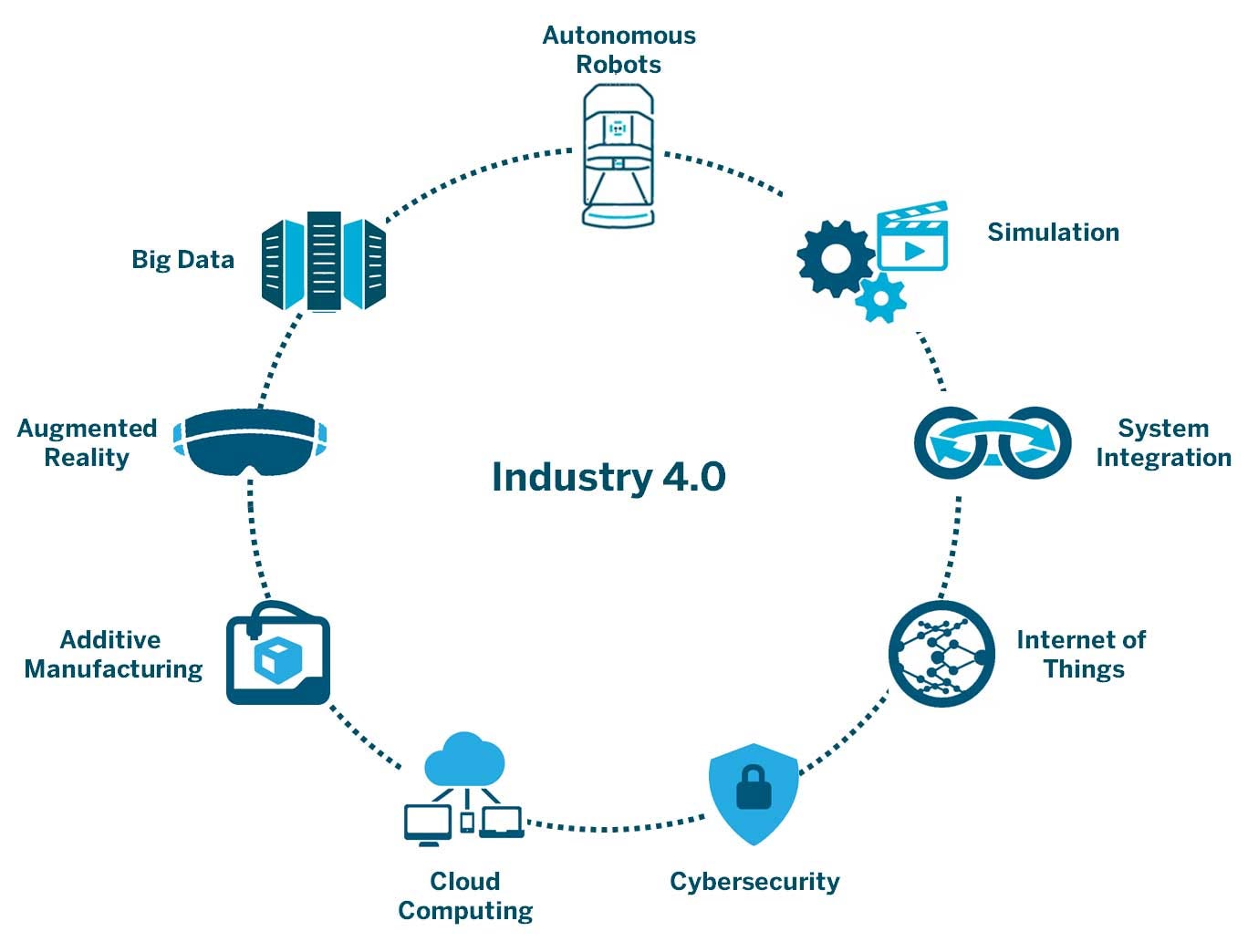

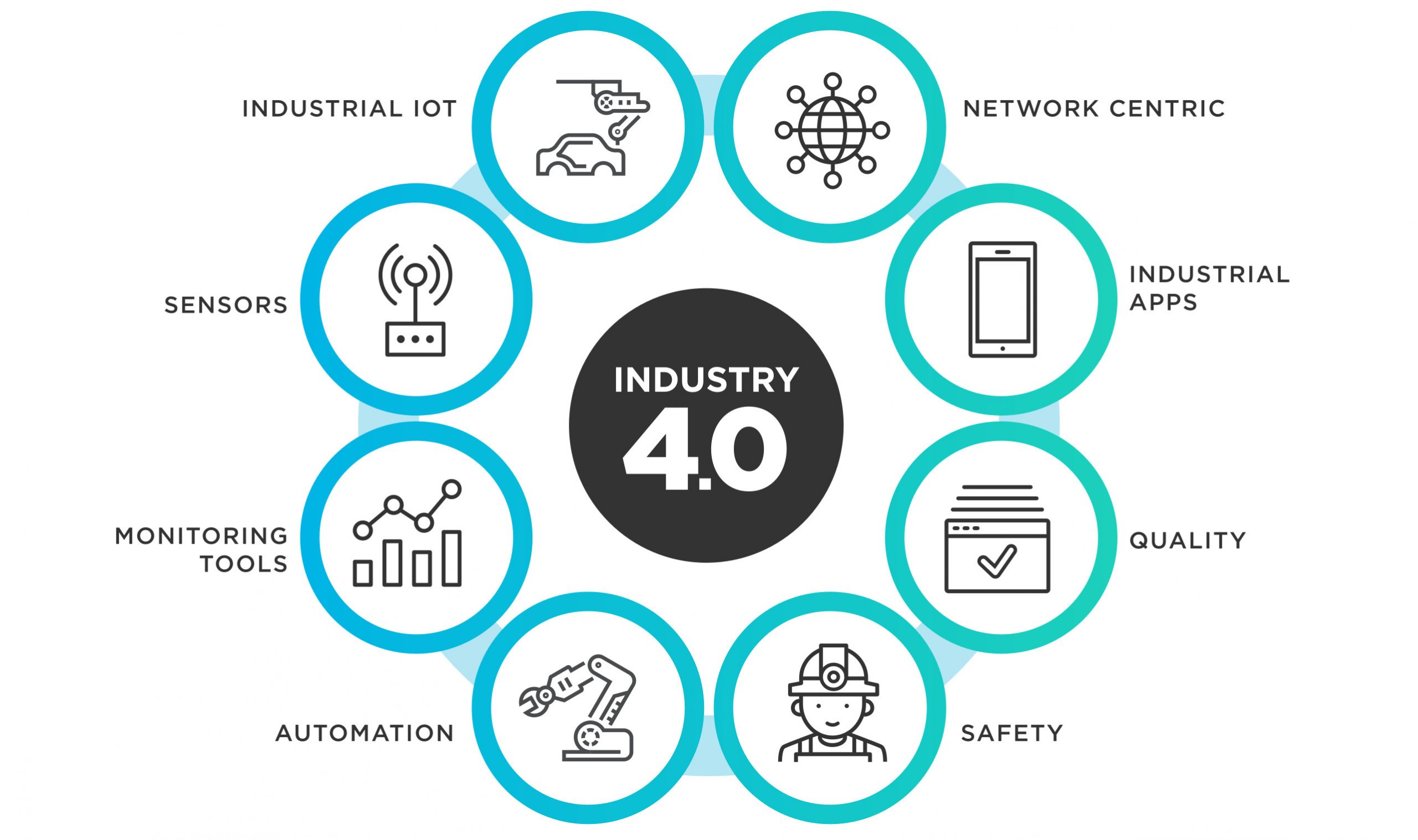

Industry 4.0 smart production systems comprise industrial systems and subsystems that need to be integrated in such a way that they are able to support high modularity and reconfigurability of all system components. In today's industrial production, manufacturing execution systems (MESs) and supervisory control and data acquisition (SCADA) systems are typically in charge of orchestrating and.. The 4th industrial revolution (Industry 4.0, I4.0) is based upon the penetration of many new technologies to the industrial world. These technologies are posed to fundamentally change assembly lines around the world. Assembly systems transformed by I4.0 technology integration are referred to here as Assembly 4.0 (A4.0). While most I4.0 new technologies are known, and their integration into.

3 Benefits of Operationalizing AI in Manufacturing

Smart Factory, Industry 4.0, Automated Manufacturing IoT Conf.Nov 10

Electronic assembly line in a manufacturing plant Stock Photo, Royalty

Smart Manufacturing, Smart Factory It’s All About Digital Transformation

Challenges in the journey of digital manufacturing Viking Analytics

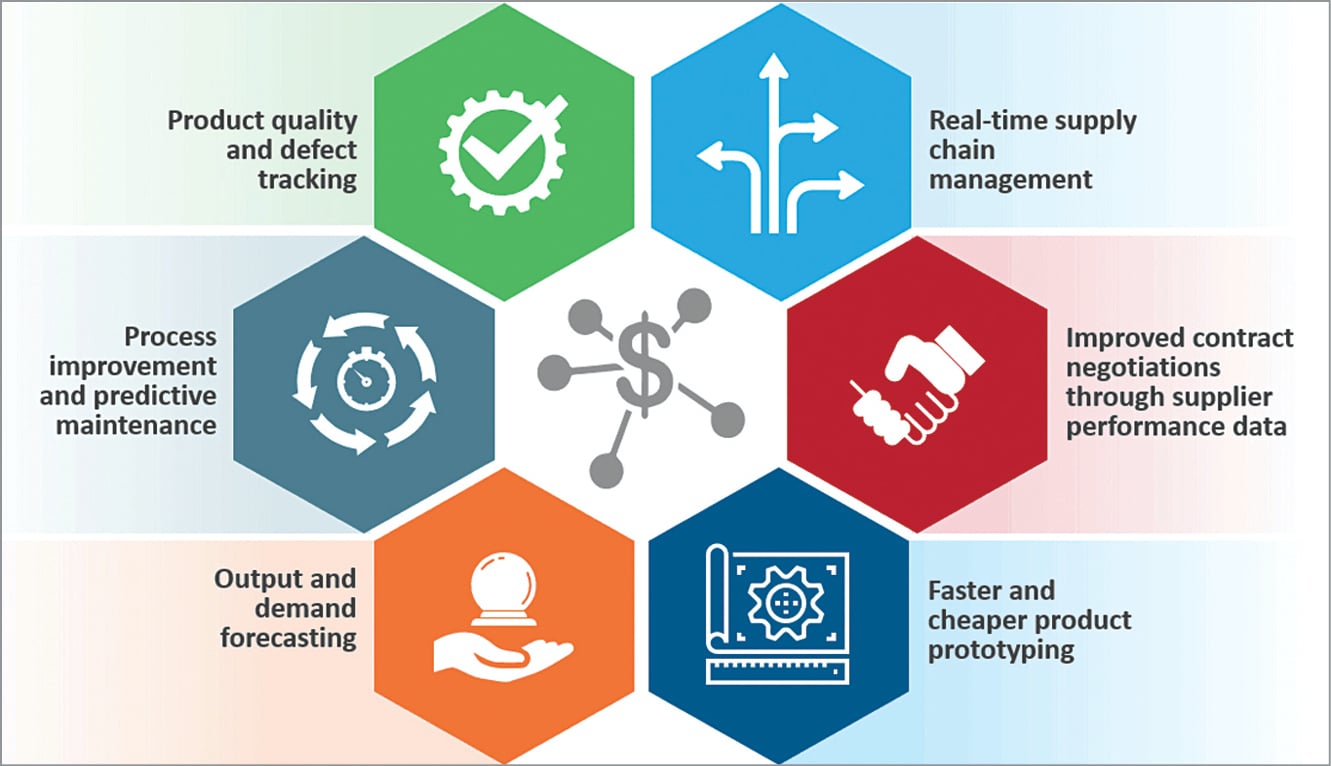

11 Excellent Ways to Improve Your Manufacturing With Data RoboDK blog

Industry 4.0 7 RealWorld Examples of Digital Manufacturing in Action

Industrie 4.0 Wie weit ist der deutsche Mittelstand? RS Components

Demonstrating the latest smart manufacturing and process control

Industry 4.0 — The Top 9 Technology Trends by Shalini Sreekanth Medium

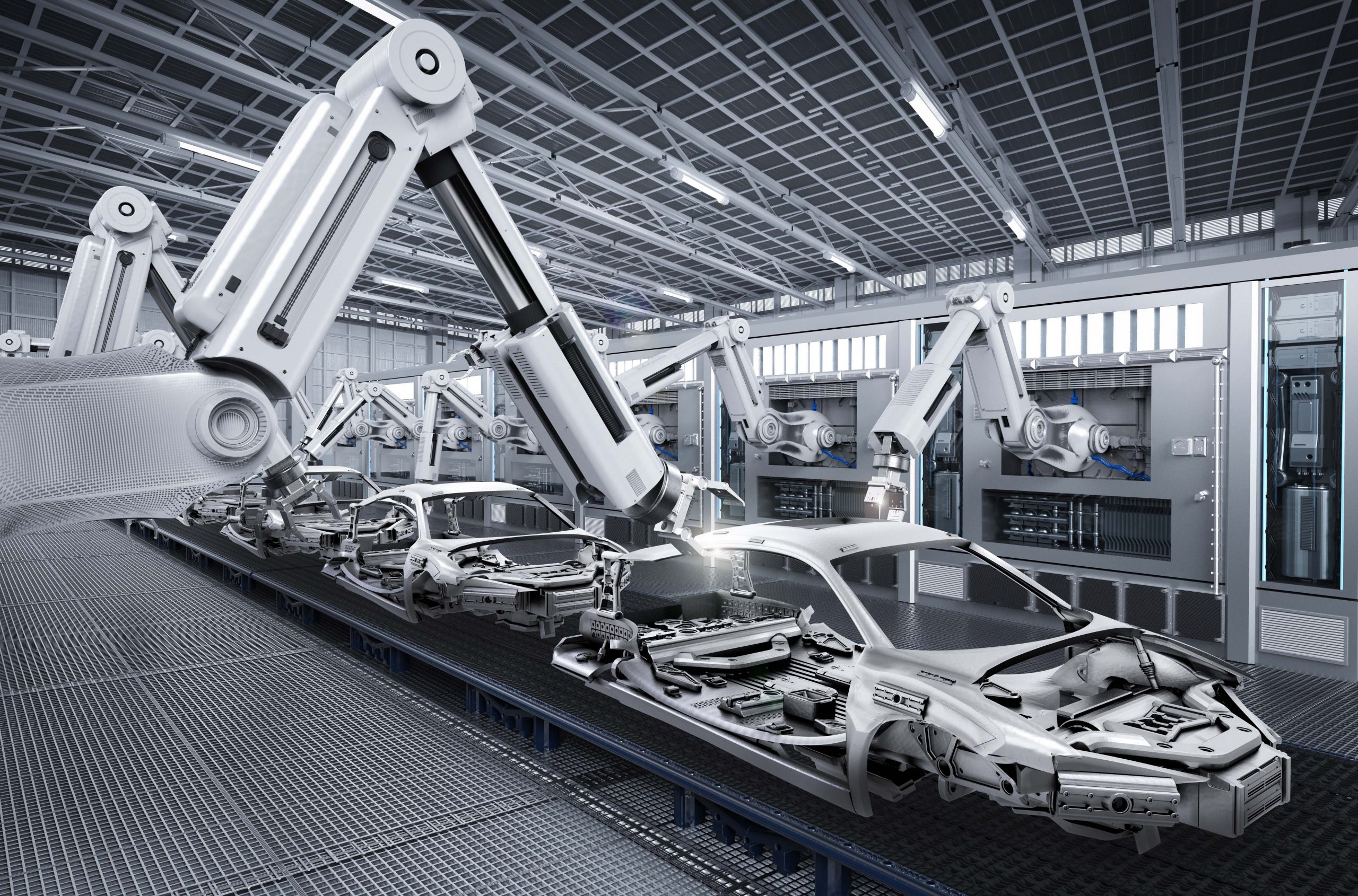

Automotive Manufacturing Automation Systems SuperTrak Conveyance

Enabling Manufacturing Innovation with the Virtual Twin Experience

Digital Transformation for a Multifunctional Manufacturing Industry

The Ultimate Guide to IoTdriven Digital Transformation in Manufacturing

Digital Transformation With Industry 4.0 Electronics For You

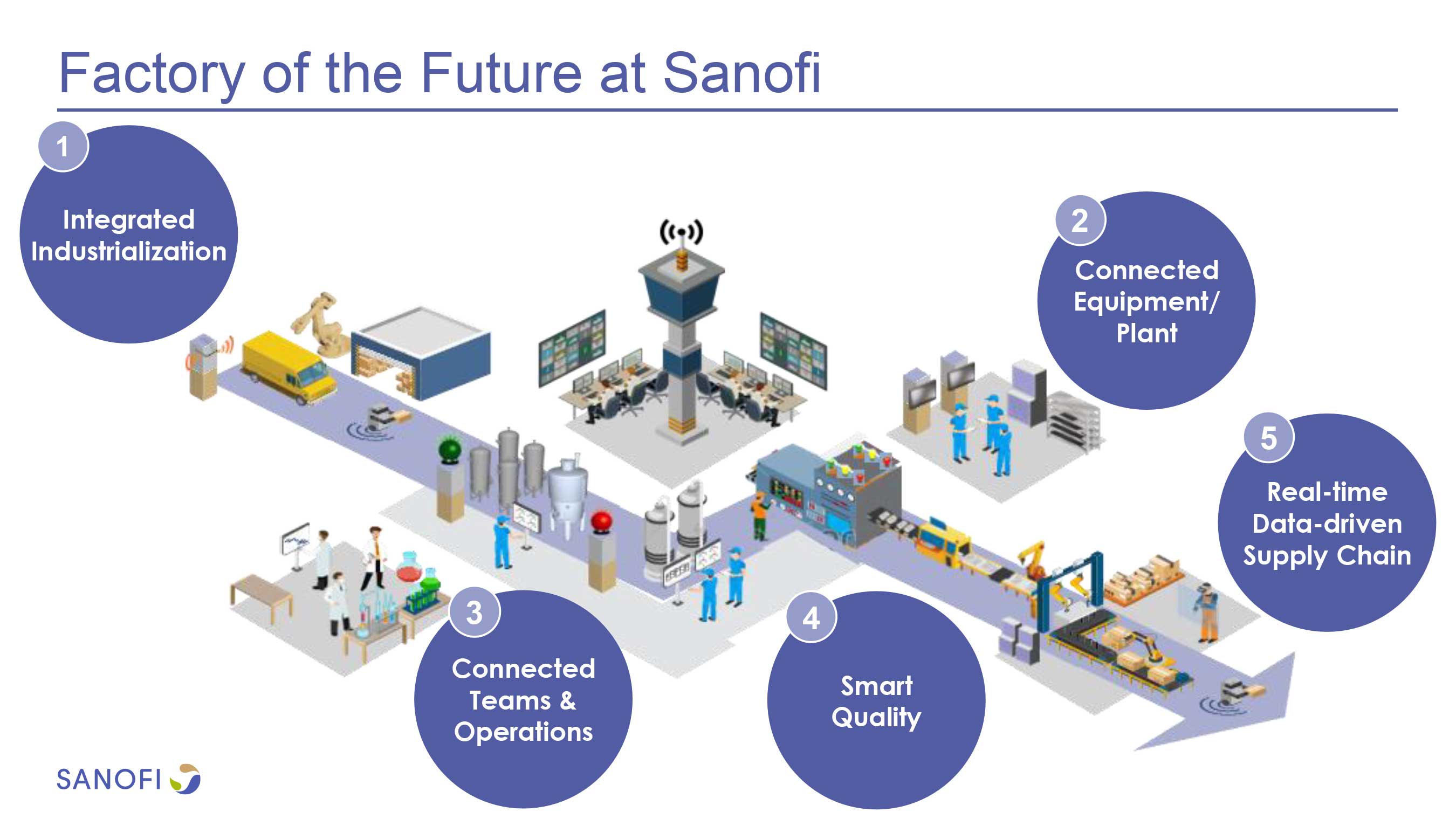

Sanofi opens its first digitallyenabled, continuous manufacturing

Industry 4.0 How Technology is Revolutionizing the Manufacturing Industry

LEAN manufacturing Qu'estce que le lean manufacturing

Trinamix announces the addition of new Industry 4.0 capabilities

6 Benefits of Business Intelligence in Manufacturing Industry Teplar

A 2020 Industry 4.0 survey by McKinsey of more than 800 businesses globally revealed three major challenge areas: financial hurdles, organizational problems, and technology roadblocks. Financial hurdles typically include the high costs associated with scaling digital deployments that don't provide short-term benefits to the organization, and therefore don't provide a strong incentive for.. Digital Manufacturing and Assembly Systems in Industry 4.0 (Science, Technology, and Management) - Kindle edition by Kumar, Kaushik, Zindani, Divya, Davim, J. Paulo. Download it once and read it on your Kindle device, PC, phones or tablets. Use features like bookmarks, note taking and highlighting while reading Digital Manufacturing and Assembly Systems in Industry 4.0 (Science, Technology.